Shervin Yousefzadeh and Dr. Arghavan Akbarieh, a postdoctoral researcher at Eindhoven University of Technology, explore how GS1 standards can enhance circularity in construction.

The construction industry, traditionally known for its resource-intensive processes, is undergoing a transformative shift towards sustainability shift towards sustainability and resource efficiency.

This change is driven by the concept of a “circular economy.” While the phrase “circular economy” may not immediately evoke environmental concerns, it fundamentally emphasises the important role of the end-of-life (EoL) phase of products in their environmental footprint.

Rather than simply discarding used product and materials, the circular economy acknowledges that there is inherent value beyond their initial use. This value could be financial or based on performance. Capturing this value allows materials to be recirculated back into the value chain, avoiding waste and reducing the need for new raw materials. The circular economy is a paradigm shift that represents a fundamental shift from the traditional extract-produce-use-waste mentality towards an extract-produce-use-reuse model.

By focusing on the EoL phase of buildings and construction products, the circular economy seeks to maintain components and materials within the value chain, ensuring the highest possible quality and minimising waste. The EoL phase is therefore not seen as the final stage, but rather as an opportunity to recover valuable resources and minimise environmental impacts.

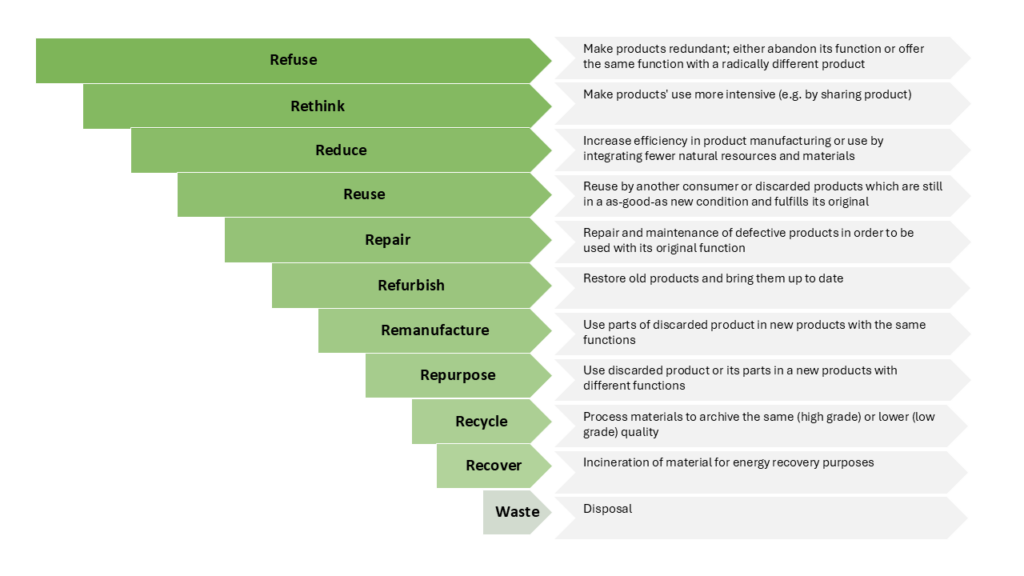

There are various ways that circularity can manifest, most of which are captured in the diagram below:

The circular economy is not just limited to products or materials. The construction industry consists of both processes and products so, to fully realise circularity in the construction, engineering, and architecture (AEC) domain, new processes have been developed to implement circularity at various levels.

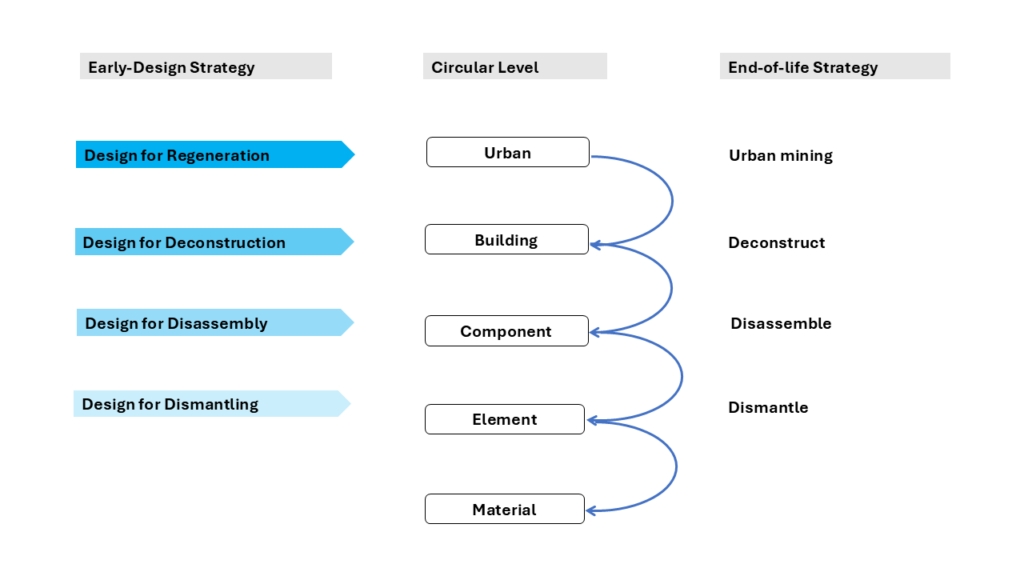

Circularity can occur at many levels in the construction sector. It can occur with individual components, products, functional layers, entire buildings, and even at the urban scale. New circular approaches and strategies have emerged to accommodate circular needs in each scale, some of which are illustrated in below:

Advantages of the circular economy in construction

There are many advantages regarding the circular economy, including:

Resource recovery and waste reduction

By recovering valuable resources at the EoL phase, the need for new raw materials is significantly reduced. This lowers the pressure of material extraction from the biosphere and allows regeneration of renewable materials such as wood, and usage optimisation of other non-renewables such as steel. Increasing reuse and recycling reduces waste and the need for landfill sites, freeing up valuable land for better uses.

Indirect carbon and energy savings

In a circular economy, significant carbon and energy savings can be achieved by avoiding the energy-intensive stages of raw material extraction, transport, and manufacturing lifecycle stages. These stages all consume substantial amounts of energy and produce high levels of carbon emissions. Reusing and recycling materials significantly reduces the need to extract and produce new ones, conserving energy and lowering carbon emissions. This is in line with climate change adaptation and mitigation strategies and will help to regenerate resources in the long-term.

Emerging roles and organisations

The shift from a linear to a circular economy requires the emergence of new roles, organisations, and systems such as marketplaces for reusables. These marketplaces provide platforms where businesses and consumers can find and buy used or refurbished products, extending their lifecycle and keeping them within the value chain.

Business opportunities

Marketplaces and alternative supply chains help increase resilience and reduce the pressure associated with extracting and producing new products from virgin materials. Reducing dependence on new materials helps to protect businesses against supply chain disruptions and price volatility.

Driving innovation

Innovative business models are now emerging, such as PAAS (product-as-a-service) which focuses on residual performance and material value. Under such models, companies retain ownership of products and materials and are responsible for maintenance, upgrades, and disposal, aligning with Extended Product Responsibility (EPR). This encourages durable design, promotes reuse, remanufacturing, or recycling, and requires a track-and-trace system to reassess and recertify products throughout their lifecycle.

Implementing circularity with GS1 standards

Effective track and trace systems require robust mechanisms for identifying and tracking each product type or instance.

This involves assigning unique identifiers, such as the Global Trade Item Number (GTIN) to products, which are then linked to detailed information.

This can include the product’s material composition and characteristics, life cycle data, circular information, EoL options and more, to ensure the proper reuse and recycling. This digital collection of this information is often referred to as a “digital product passport” or “DPP”.

By implementing unique GS1 identifiers such as GTINs, products and materials in the construction industry can be tracked from the production stage through to end-of-life. This tracking is further enhanced by digital product passports that detail each product’s material composition, lifecycle data, and recycling information. This make it easier to recover and repurpose materials at their end of life, significantly reducing waste and the demand for virgin resources.

Furthermore, these identifiers help stakeholders across the supply chain comply with regulatory requirements and sustainability certifications that are increasingly demanded by consumers and governing bodies. Compliance can be made simple through the transparency and traceability offered by GS1 standards, ensuring that all material claims can be verified, building trust and improving collaboration across industry.

The adoption of GS1 standards supports the creation of efficient marketplaces for reclaimed materials. By using standardised identifiers, materials that are recovered, tracked and recertified can be easily catalogued and shared in databases making them available for reuse.

GS1 standards also play a vital role in the effective management of materials across their entire lifecycle. This includes EoL strategies such as recycling and is essential for the effective implementation of a circular economy model. These fully interoperable global standards provide a common language that enables clear communication across various stakeholders in the supply chain, from manufacturers right through to consumers, ensuring transparency and traceability at every stage of a product’s lifecycle.

In conclusion, GS1 standards not only enhance the operational efficiency of circular economy practices in the construction industry, they also support sustainability by ensuring that materials can be effectively reused and recycled. This holistic approach transforms waste into valuable resources, reducing environmental impact, opening up economic opportunities, and driving the industry towards a more sustainable and resilient future.

Copyrights to GS1 UK