The minimum size of the barcode depends on the barcode type and the intended scanning environment (point-of-sale, warehouse, etc). Generally, bigger barcodes scan more reliably. All GS1 barcodes have a minimum and maximum size requirement. Your printer should be able to advise on the suitable size for your packaging, printing method and design.

All GS1 barcodes have certain height requirements. For some barcodes, like EAN/UPC, the height must remain in proportion to the width to avoid scanning problems. This is because of the way the scanner scans this type of barcode. Other barcodes, such as ITF-14 and GS1-128, have a set height with some exceptions for different applications. Regardless, you should avoid reducing the barcode height (known as truncation) from what is specified. At the wrong height, a barcode may not scan first time. Worse, it may not scan at all – therefore requiring manual input of data, which introduces errors and inefficiencies.

Quiet zones are the clear areas before the first bar and after the last bar on a barcode. For two-dimensional barcodes, the quiet zone is the light area around the barcode.

The quiet zone is very important – it tells the scanner where the beginning and end of the barcode is. If it is reduced or eliminated, the barcode may not be able to be scanned.

The minimum size of the quiet zone depends on the size of the barcode. It is recommended to allow slightly more than the minimum required quiet zones, in case of ink spread or plate registration issues. You can check the GS1 General Specifications for further information.

All barcodes should include human readable interpretation – that is, the characters (letters and numbers) that can be read by people – in case the barcode does not scan.

The location of the human readable interpretation depends on the barcode type. You can check the GS1 General Specifications for further information.

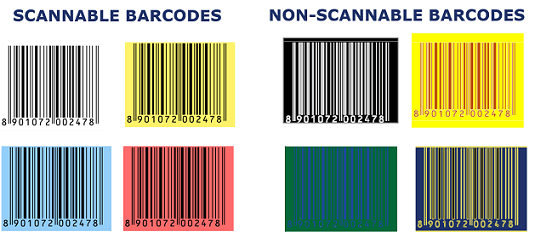

Scanners read barcodes using infrared light sources that identify the contrast between the two colours – so it is important to use dark bars on a solid, light background.

The most reliable colour combination is black bars on a white background, although other combinations are possible as shown below.

Consult your printer or GS1 UAE if you are uncertain about your options.

It is important to choose a suitable substrate; that is, the material the barcode is printed on. Different substrates affect the quality of the barcode and thus its ability to scan.

You should:

- Avoid high gloss (reflective) substrates

- Avoid transparent or semi-transparent backgrounds

- Avoid placing transparent wrappers over the printed barcode

Common ways to apply barcodes to trade items include:

- Pre-printed labels – a printer or label service can print barcodes onto labels, or you can print them on-site using specialised printing equipment

- On-site direct printing on packaging – you can print the barcode directly onto packaging using specialised printing equipment

- Printing on packaging at source – you can incorporate barcodes into packaging artwork

Please note that direct part marking is an option for some applications, such as laser etching. GS1 has standards to support this method of print for certain applications. Please contact us for further assistance.

You should regularly check your printing standards to ensure acceptable print quality and ink spread, and to ensure that the barcodes meet all of the requirements listed above.